Pin for X348 X458 X678 Chain | Overhead Conveyor Components

- group name

- Drop Forged Rivetless Chain

- Min Order

- 50 meter

- brand name

- CamelConvey Conveyor Chain Manufacturer

- model

- Pin for Chain

- Nearest port for product export

- Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, DDP, Express Delivery

- Acceptable payment methods

- T/T, L/C

- update time

- Sun, 08 Mar 2026 09:44:40 GMT

Paramtents

Material 40Cr

Sample Available

Packging & Delivery

-

Min Order50 meter

Briefing

Detailed

Pin for X348 X458 X678 chain | Conveyor components Description:

Pin for X348 X458 X678 chain | Conveyor components Pictures:

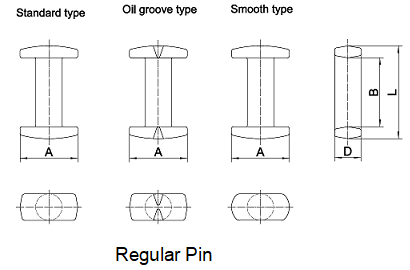

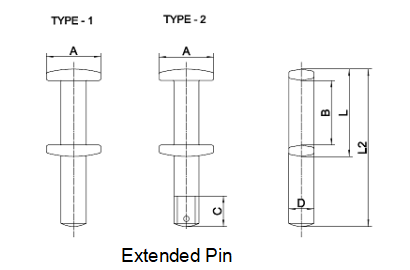

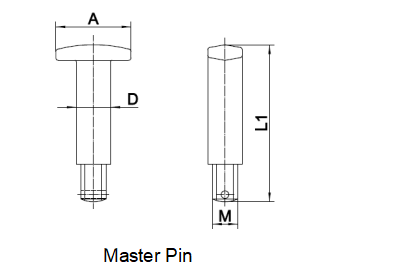

Pin for X348 X458 X678 chain | Conveyor components Schematic Diagram:

Pin for X348 X458 X678 chain | Conveyor components Specification:

Chain No. | Pitch | Pin Diameter | Pin Length | Other Dimensions | |||||

P | D | L | A | B | C | M | L1 | L2 | |

X678 | 6" | 0.874" | 3.03" | 1.89" | 2.26" | 1.14" | 0.63" | 3.86'' | 5.35'' |

152.4mm | 22.2mm | 77mm | 48mm | 57.5mm | 29mm | 16mm | 98mm | 136mm | |

X458 | 4'' | 0.625'' | 2.24'' | 1.26'' | 1.635'' | 0.98'' | 0.47'' | 3.19'' | 4.41'' |

101.6mm | 15.88mm | 57mm | 32mm | 41.5mm | 25mm | 12mm | 81mm | 112mm | |

X348 | 3'' | 0.5'' | 1.81'' | 0.98'' | 1.3'' | - | - | - | - |

76.2mm | 12.7mm | 46mm | 25mm | 33mm | - | - | - | - | |

Pin for X348 X458 X678 chain | Conveyor components Overview:

Trustworthy CamelConvey

In I-beam conveyors, drop-forged pins play a critical role in maintaining smooth and reliable operations. Over time, these components undergo significant stress and wear, and proper inspection is essential to avoid costly downtime or accidents. From the video, by following these best practices and maintaining thorough records, companies can significantly reduce the likelihood of unexpected pin failure, ensuring safe and efficient conveyor operation. Regular, proactive inspections not only extend the lifetime of the pins but also contribute to the overall safety and reliability of the conveyor system.